Main Cargo Door (MCD) Sill Protector Conversion (B727-200F)

>> Sunday, January 2, 2011

MCD Sill Protector Conversion Study

Introduction

Sill Guard or Sill Protector is installed at the cargo door entrance and protects the door sill from damage during cargo loading and unloading operations. The protector is equipped with rollers mounted on the plate to provide easy movement of the pallets through the door opening. Pallet guides, at the door edge of the sill guard, guide the pallets and prevent damage to the side door jambs.

Background

1. There are various door sill protectors.

2. Some aircraft freighter installed with Global Aerospace Technology Corporation Inc. (Gatco) fly-away sill which is a one-piece unit that covers the entire cargo door sill and attached to the seat track as shown in fig 1. This sill protector is restricted in 1-Directional movement viz. raise up (deployed) to enable MCD closing and lower (stowed) to enable loading and off-loading operations.

3. Aircrafts installed with Brownline detachable sill which is combined of fwd and aft sills as one sill that covers the entire cargo door sill and attached to the seat track as shown in fig 2. This sill protector is detachable type which install before onload / offload by engage it’s clevis blocks on hinge brackets; remove and stowed when not in used by disengage the clevis blocks from the hinge brackets.

Reason for Report

1. This study reviews the differences of two types of door sill protector and gathers information from OEM/Pemco to see how the problem caused by door sill protector may be improved.

2. This study will also look into the possibility of standardize sill protector.

Data

1. Aircrafts installed with Brownline detachable sill which is combined of fwd and aft sills as one sill that covers the entire cargo door sill and attached to the seat track as shown in fig 2. This sill protector is detachable type which install before onload / offload by engage it’s clevis blocks on hinge brackets; remove and stowed when not in used by disengage the clevis blocks from the hinge brackets.

Reason for Report

1. This study reviews the differences of two types of door sill protector and gathers information from OEM/Pemco to see how the problem caused by door sill protector may be improved.

2. This study will also look into the possibility of standardize sill protector.

Data

1. Both sill protectors have their pros and cons. Refer to Table 1 for more details.

| Fly-Away Sill Protector | Brownline Sill Protector |

| Pro · Convenient in cargo loading and unloading process. · Stowed at where it installed instead of taking other space in aircraft. | Pro · Detach after cargo loading/unloading process thus no MCD closing problem issue. |

| Cons · Prone to have deformation on shaft that will cause difficulty for MCD to fully close. – see fig. 3 & 4 | Cons · Prone to drop off the aircraft due to the short hinge bracket unable to hook the sill protector tightly. – see fig. 5 · Has to sacrifice existing spare tail steady stowage location in lavatory bulkhead for detachable sill protector stowage attachment – see fig. 6 |

| Table 1: Pro and Cons among both sill protectors | |

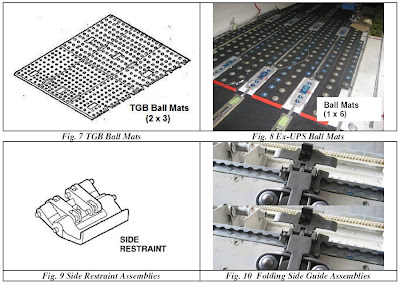

2. Ball mats among all freighter aircraft are different in design. – see fig. 7 & 8. Both ball mats adjacent to the cargo door (outboard) have 6 cutouts to allow installation for side restraint assemblies and folding side guide assemblies respectively. – see fig. 9 & 10

3. B727 acfts are having same seat tracks at LBL 62.5 (STA 507.531 – 5 to STA 652.469 +5), BL 45.5(left & right), 24.75 (left & right) and 0.0 (at centerline of aircraft) as typical freighter configuration. – see fig. 11. However, acft with Brownline detachable sill protector will have an additional seat track located from STA 507.531 +11 to STA 652.469 -11 and at LBL 57.5 – see fig. 12

Information from STC Holder Pemco

1.) Pemco is the STC holder for some of B727 P to F conversion via STC SA 1509SO and 1543SO.

Information from OEM Gatco - TGB

1.) Gatco is the OEM for the fly-away sill protector, ball mats, end restraints and side retraints.

2.) IPC provided by Gatco in order to replace/repair the bended shaft as shown in fig. 3 above – see Discussion

3.) P/ns for shafts are 70098-4-168, 70098-4-328 and 70098-4-198 respectively.

Information from OEM AAR Brownline

1.) AAR Brownline is the OEM for the detachable sill protector, seat track, ball mats, end restraints and folding side guides.

2.) Alternative receptacle that compatible with detachable sill protector is pending from AAR – see Discussion

Discussions and Findings

1.) Some B727 is reported to have difficulty of MCD closing problem due to the legs on sill protector is not retracted to stowed position when sill protector is raise. These dislocated legs will obstruct the MCD latch to be latched on the door spool. – see fig.3 above and fig. 13 & 14

2.) Fig. 15 shows the illustrated parts for sill protector. The leg is moving by the shaft installed on it and link with the linkage on sill protector clevis so that the leg will move parallel with sill protector raise or lower. Fig. 16 shows the leg sits on the door spool when sill protector is lowered to allow protection on door sill during loading/unloading process.

3.) The bended shafts are more likely located at middle part of sill protector and this could be likely due to bad handling during lowering the sill protector.

4.) 3 alternatives are suggested to solve the main cargo door closing problem as stated below:-

a) Replace bended shaft

b) Modify sill protector hinge to be receptacle type and change the sill protector to Brownline detachable sill protector. – see fig. 17

c) Modify sill protector to Brownline detachable sill protector.

· Heavy mod which involve change of ball mats from 2x3 to 1x6, change of side restraint to folding side guide, add additional seat track at LBL 57.5, change of Gatco sill protector to Brownline sill protector, change of Gatco end restraint to Brownline end restraint.

5.) Some B727 freighter has been reported that detachable sill protector does not perfect fit with the hinge bracket and is slightly moveable. Subsequently the sill protector is prone to drop off aircraft during cargo loading/unloading.

6.) Physically check found the hinge bracket is too short to hold the sill bracket clevis block in tight manner. However, the height of the hinge bracket is limited in order to avoid friction with igloo (cargo). – See fig. 18

Recommendations

1.) Replacement of bended shafts is the simplest and cost effective way to solve MCD closing issue – info

2.) If replacement of bended shafts is acceptable instead of standardizing door sill protector configuration, the following actions have to be carried out:-

a) Informed staff/3rd party to lower the sill protector prior loading and unloading process in proper way instead of free fall.

b) Carry out NDT on the hole of sill protector legs, links and clevis to ensure free of cracks.

c) Pre-order more shafts as preventive action.

d) Ensure all legs have retracted at its’ stowed position instead of blocking MCD from closing.

e) Issue sill protector shaft replacement.

Conclusion

So far there is no delay induced by Door Sill Protector. Out of 2 alternatives, the simplest and cost effective way should be replacing the bended shaft and monitoring how far these shafts can withstand from deformation. To standardize the door sill protector will involve a heavy and expensive mod and aircraft has to be ground for some time to allow modification carried out by Pemco.

Read more...